F150 Hub Assembly Lifespan: What You Need to Know

Figuring out the f150 hub assembly lifespan can be tricky for anyone new to truck maintenance. There’s a lot of talk about bearings, seals, and how they wear out. Don’t worry, it’s not as difficult as it sounds. This post aims to simplify things and give you a straightforward guide. We’ll explore the factors affecting how long your hub assembly lasts and offer easy steps to help you keep your truck running smoothly. Get ready to learn!

Key Takeaways

- The average f150 hub assembly lasts between 75,000 and 150,000 miles, but this varies.

- Driving habits and terrain significantly impact how long your hub assembly lasts.

- Regular inspections can help you catch problems early and extend your hub assembly’s life.

- Understanding the warning signs of a failing hub assembly can save you money.

- Proper maintenance, such as timely wheel bearing greasing or replacement, is very important.

Understanding the F150 Hub Assembly

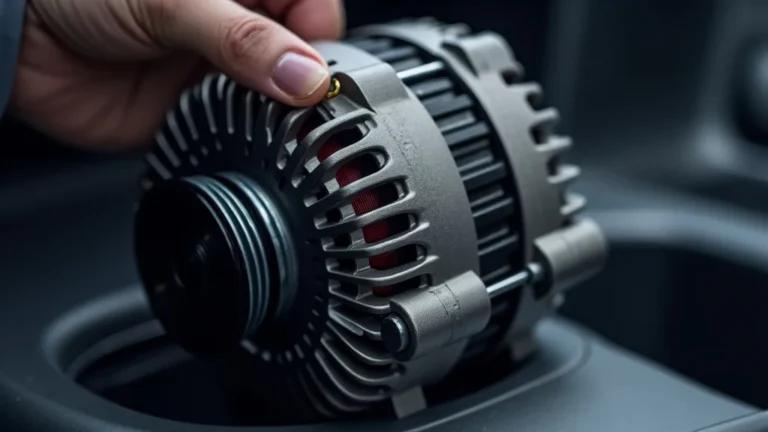

The hub assembly, also known as the wheel hub bearing, is an essential part of your F150. It allows the wheels to spin freely while supporting the weight of the truck. This assembly includes the wheel bearing, which reduces friction, allowing the wheel to rotate with minimal resistance. It also houses the studs that secure the wheel to the truck and often includes the ABS (Anti-lock Braking System) sensor. The lifespan of this component greatly depends on various factors. Learning about these key factors can help drivers take proper care of their F150 and predict potential issues.

Components of the Hub Assembly

Several components work together within the hub assembly to ensure the wheel can rotate smoothly and safely. Each part plays a vital role. Knowing what these components are and what they do can help you spot potential problems before they lead to bigger issues. Being familiar with these parts lets you understand where issues might come from and how to address them quickly. Let’s explore the key parts that are essential for wheel function.

- Wheel Bearings: These are the core of the hub assembly. They’re designed to reduce friction and allow the wheel to spin easily. They often come in the form of ball or roller bearings, depending on the truck’s design. As these bearings wear out, you might hear noises or feel vibrations when driving.

- Hub Housing: This sturdy part encases the wheel bearings and other components, protecting them from dirt and moisture. It is made to handle the stresses of driving. A damaged hub housing can cause bearings to wear faster or fail completely.

- Wheel Studs: These are bolts that stick out from the hub, allowing you to attach the wheel to the assembly. They’re essential for keeping the wheel securely in place. If these get damaged or stripped, it can be dangerous, and you’ll need to replace the hub assembly.

- ABS Sensor: Many hub assemblies also include an ABS (Anti-lock Braking System) sensor. This sensor tells the truck’s computer how fast each wheel is turning. This information is key for your brakes. A faulty sensor might trigger the ABS light on your dashboard, and it could affect how the brakes work.

How the Hub Assembly Works

The hub assembly works in harmony to allow the wheel to turn properly. When you drive, the wheel rotates on the bearings within the hub. These bearings are greased to reduce friction and heat. The wheel studs hold the wheel firmly to the hub, and the ABS sensor monitors wheel speed. This system handles the weight of the truck and the forces from driving. Understanding how this intricate system works will help you understand how it can fail.

- Supporting the Load: The hub assembly supports the truck’s weight. The bearings inside the assembly are made to handle the heavy loads and stresses that come from driving.

- Enabling Rotation: The wheel bearings allow the wheel to spin with minimal friction. This ensures that the wheel rotates smoothly. Without good bearings, the wheel would drag, making driving difficult.

- Ensuring Safety: The wheel studs hold the wheel safely onto the truck. Also, the ABS sensor helps the anti-lock braking system work, improving safety by preventing wheel lockup during braking.

- Transferring Power: In some trucks, the hub assembly also helps transfer power from the drivetrain to the wheels, especially in 4-wheel drive or all-wheel drive systems.

Signs of Hub Assembly Problems

Identifying problems with your hub assembly early on can save you money. You should pay close attention to any strange sounds or changes in the way your truck handles. Ignoring these signs can lead to more significant damage and potentially unsafe driving conditions. Detecting these signals early lets you fix issues before they become critical. Common problems include noises, vibrations, and poor handling, which can impact safety.

- Unusual Noises: A common sign of trouble is a humming, growling, or grinding sound coming from the wheel area. This usually gets louder as you speed up.

- Vibrations: You might feel vibrations in the steering wheel or through the floorboard. This is especially noticeable at certain speeds.

- Loose Wheel: When you jack up your truck and try to rock the wheel, if it moves from side to side, that’s a sign of a loose hub assembly.

- Uneven Tire Wear: Problems with the hub assembly can cause uneven tire wear. The tire might wear more on one side than the other.

- ABS Light: The ABS light on your dashboard might come on. It can indicate a problem with the ABS sensor built into the hub assembly.

Factors That Affect F150 Hub Assembly Lifespan

Many things can influence how long your F150 hub assembly will last. These factors range from your driving style to the type of roads you usually travel on and how often you maintain your truck. Understanding these factors is key to extending the life of your hub assembly and avoiding costly repairs. Some factors are about the truck’s environment and use, whereas others relate to maintenance.

Driving Habits and Terrain

How you drive and the kind of roads you travel on make a huge difference in the life of your hub assembly. Aggressive driving, like quick starts and stops, can put extra stress on the bearings. Rough roads, with potholes and bumps, create impacts that wear down the assembly. Consider your driving style and the roads you travel. Being aware of these can help you adjust your habits to help your hub assembly last longer. Driving carefully and choosing roads that are in better shape makes your F150 more reliable.

- Aggressive Driving: Quick starts, hard braking, and fast turns put extra strain on the hub assembly. These actions create more heat and wear on the bearings.

- Road Conditions: Driving on rough roads, with potholes or bumps, causes significant impacts. This can lead to faster wear and tear on the hub assembly.

- Off-Roading: If you drive off-road frequently, the hub assembly is subject to dirt, water, and impacts, which can shorten its life.

- Speed: Higher speeds put more stress on the hub assembly, especially on rough roads. The faster you drive, the more wear you may see.

Road Salt and Weather Conditions

Weather and environmental conditions can significantly impact the hub assembly lifespan. In areas with harsh winters, road salt and de-icing chemicals are used, which can corrode the components. High humidity and moisture can also increase the rate of wear. Exposure to extreme temperatures can cause the grease in the bearings to break down faster. Protecting your hub assembly from these elements, or dealing with them if they occur, is key to the truck’s longevity.

- Road Salt: Road salt used in winter can cause corrosion of the hub assembly components, leading to premature failure.

- Moisture: High humidity and water exposure can also accelerate corrosion and rust on the bearings and other parts.

- Extreme Temperatures: Both extremely cold and hot temperatures can affect the grease inside the bearings, causing it to lose its ability to lubricate effectively.

- Driving in Standing Water: Driving through deep water can introduce water into the hub assembly, which can wash away the grease and cause rust.

Maintenance Schedule and Quality of Parts

Regular maintenance and the quality of parts used during repairs are essential. Following your truck’s maintenance schedule helps you catch potential problems early and keep the hub assembly running smoothly. Using high-quality replacement parts is crucial for ensuring durability and performance. Consider what is included in your routine maintenance, such as inspections and lubrication. When it’s time to replace parts, using quality parts is a smart move.

- Regular Inspections: Routine inspections by a mechanic can help catch problems early. They can spot signs of wear or damage before they become severe.

- Wheel Bearing Greasing: Proper lubrication of wheel bearings is crucial. Some hub assemblies are sealed and cannot be greased, while others may benefit from periodic greasing to keep friction low.

- Quality of Replacement Parts: Using high-quality replacement parts can make a big difference in the lifespan of the hub assembly. Cheaper parts may fail sooner.

- Following the Maintenance Schedule: Stick to your truck’s recommended maintenance schedule. It includes important steps, such as checking and replacing parts when needed.

Extending the Life of Your F150 Hub Assembly

You can take several actions to make your hub assembly last longer. Some things involve how you drive, while others are about the care you give your truck. By following these easy steps, you can help protect the hub assembly from damage and extend its lifespan. Making some adjustments to your driving and caring for your truck can result in fewer trips to the mechanic.

Regular Inspections and Maintenance

Regular inspections and maintenance are the keys to a long-lasting hub assembly. Inspections allow you to detect potential problems early on, before they lead to more significant damage. Keeping up with routine maintenance, such as greasing bearings and checking components, can significantly extend the assembly’s life. Regular maintenance helps avoid unexpected breakdowns and keeps your truck reliable. Remember that regular inspection is critical, and these checks do not take long.

- Regular Visual Inspections: Regularly check the hub assembly for any signs of damage, such as rust, leaks, or loose components. This can be done when changing tires.

- Listen for Noises: Pay attention to any unusual sounds coming from the wheel area. These noises often indicate a problem.

- Check for Play: Test for any side-to-side play by rocking the wheel. This could be a sign of a bad bearing.

- Wheel Bearing Greasing: If your hub assembly uses wheel bearings that can be greased, make sure to lubricate them as recommended.

Driving Habits and Road Awareness

Your driving style and your awareness of road conditions play a big role in your hub assembly’s life. Avoiding aggressive driving, such as quick starts and hard braking, helps reduce stress on the bearings. Being mindful of road conditions and adjusting your speed accordingly can also help. Driving carefully and being aware of your surroundings can help to prevent the need for early hub assembly replacement and keeps you and your passengers safer.

- Avoid Aggressive Driving: Avoid quick starts, sudden stops, and sharp turns. These actions put extra stress on the hub assembly and can cause more wear.

- Drive Carefully on Rough Roads: When driving on rough roads with potholes or bumps, slow down. This minimizes the impact on the hub assembly.

- Be Aware of Road Hazards: Watch out for potholes, speed bumps, and other road hazards that can damage the hub assembly.

- Avoid Driving Through Deep Water: Water can get into the hub assembly and cause problems. Avoid driving through standing water whenever possible.

Choosing the Right Replacement Parts

Choosing the right parts is essential when it’s time to replace the hub assembly. You can select genuine OEM (Original Equipment Manufacturer) parts or high-quality aftermarket options. Using premium replacement components ensures that your new hub assembly will last as long as possible. High-quality parts ensure that the hub assembly works reliably. The right choices can save you money and headaches in the long run.

- OEM vs. Aftermarket: OEM parts are made by the same company that made your truck. Aftermarket parts are produced by other companies. Both can be a good choice, but look for quality.

- Research the Brand: Not all aftermarket parts are the same quality. Look at customer reviews and compare brand reputations before purchasing.

- Consider Warranty: Check the warranty on the replacement part. A longer warranty often means the manufacturer trusts its product.

- Choose a Reputable Source: Buy parts from reputable auto parts stores or trusted online retailers.

F150 Hub Assembly Replacement

Knowing when and how to replace your hub assembly is essential for keeping your truck running safely and efficiently. If you notice signs of a failing hub assembly, it is usually best to replace it as soon as possible. The following information will give you an overview of the replacement process. The steps and tools needed may vary depending on the year of the truck and the model. However, following these steps will provide the best possible results.

When to Replace Your Hub Assembly

Deciding when to replace your hub assembly is essential. The right time depends on various factors, including the type of driving you do and the condition of the hub assembly itself. When you see signs of wear or failure, it’s best to replace the assembly promptly. Putting off replacement can lead to more serious issues, such as wheel separation, and may be a safety concern. Being able to spot the signs of problems helps you make the call.

- Listen for Unusual Noises: If you hear a grinding, humming, or growling sound, it’s a clear indicator that the hub assembly needs to be replaced.

- Feel for Vibrations: Notice any vibrations in the steering wheel or through the floorboard. These vibrations could indicate that something is wrong.

- Check for Play: If you jack up your truck and find any play or looseness when you try to move the wheel, this could mean the bearing is damaged.

- The ABS Light: If the ABS light is on, there could be a problem with the ABS sensor, which is part of the hub assembly.

The Replacement Process

Replacing the hub assembly can seem like a complex job. However, with the right tools and guidance, you can complete the work yourself. Safety is the most important thing. Make sure you use jack stands, and follow all safety measures. This section will walk you through the key steps involved in replacing the hub assembly. Remember, it’s better to be safe than sorry, so take your time and follow the instructions carefully.

- Prepare the Truck: Park your truck on a level surface, engage the parking brake, and then loosen the lug nuts on the wheel. Lift the truck with a jack and secure it with jack stands.

- Remove the Wheel: Fully remove the lug nuts and the wheel.

- Disconnect the Brake Caliper: Carefully remove the brake caliper from the rotor. Secure the caliper, so it doesn’t hang by the brake line.

- Remove the Rotor: Take the brake rotor off the hub assembly. This allows you to access the hub assembly itself.

- Disconnect ABS Sensor: If your hub assembly has an ABS sensor, disconnect it from the wiring harness.

- Remove the Hub Assembly: Unbolt the hub assembly from the spindle or knuckle. This often involves removing several bolts.

- Install the New Hub Assembly: Put the new hub assembly in place. Then, tighten the bolts to the torque specifications provided by the manufacturer.

- Reconnect Components: Reinstall the rotor, brake caliper, and ABS sensor (if applicable).

- Reinstall the Wheel: Put the wheel back on and tighten the lug nuts to the manufacturer’s specified torque.

- Lower the Truck: Lower the truck and double-check all connections. Take your truck for a test drive to make sure everything works correctly.

Professional Help vs. DIY

Deciding whether to do the hub assembly replacement yourself or get professional help is a common question. This decision depends on your mechanical skills, access to tools, and your budget. DIY is usually the more affordable option if you have the skills and tools. On the other hand, if you are not sure, or if the job seems too complex, it’s best to have a mechanic do the work. The goal is to get the job done right and safely, so consider the pros and cons of both ways. Weigh the cost, time, and your own level of confidence.

| DIY | Professional | |

|---|---|---|

| Cost | Generally less expensive (cost of parts only) | More expensive (labor costs added) |

| Time | Can take longer, depending on your experience | Quicker, but depends on shop scheduling |

| Tools | Requires specific tools, possibly including a torque wrench | Shop has necessary tools and equipment |

| Experience | Requires some mechanical skill and mechanical knowledge | No experience needed |

| Warranty | No warranty on labor | Warranty on both parts and labor is often provided |

Frequently Asked Questions

Question: How often should I check my hub assembly?

Answer: It’s a good idea to check your hub assembly during every tire rotation or at least twice a year. If you notice any unusual sounds or handling problems, inspect it sooner.

Question: What’s the main cause of hub assembly failure?

Answer: The most common causes of hub assembly failure include wear and tear from normal use, corrosion from road salt and moisture, and damage from impacts, such as hitting potholes.

Question: Can I drive with a bad hub assembly?

Answer: It’s not advisable to drive with a failing hub assembly. Ignoring the warning signs may lead to more serious issues, such as complete wheel failure, and could be a safety risk.

Question: How much does it cost to replace a hub assembly?

Answer: The cost to replace a hub assembly depends on several things, including the cost of parts, your location, and whether you do the work yourself. The cost varies from $200 to $600 per assembly.

Question: How do I know if the hub assembly is causing the ABS light to come on?

Answer: If the ABS light is on, the computer thinks there may be a problem with the ABS sensor built into the hub assembly. A diagnostic scan tool can help identify the exact issue.

Final Thoughts

The f150 hub assembly lifespan is something you can manage with some care and maintenance. Remember that understanding how the hub assembly works helps you to recognize problems early. You can extend the life of your hub assembly by using careful driving habits, paying attention to the road, and using premium replacement parts. Keep a close watch on your truck, and get regular inspections to address problems promptly. By doing these things, you can improve your truck’s reliability and keep it running smoothly for many miles. Take care of your F150, and it will take care of you!