F150 Brake Fade: Common Causes and How To Spot It

If you’re new to driving or working on cars, dealing with f150 brake fade causes can seem a bit tricky. It happens when your brakes start to lose their stopping power, and it’s a common issue that can be a little scary. But don’t worry! This post will explore the main reasons why this happens, and show you how to identify the problem and what you can do about it. We’ll break everything down step-by-step, making it easy to see how your truck’s brakes work and what goes wrong.

Key Takeaways

- Brake fade occurs when your brakes lose effectiveness due to heat.

- Common causes include overheated brake pads and rotors.

- Driving habits significantly influence the likelihood of brake fade.

- Knowing how to identify the symptoms can prevent serious accidents.

- Regular maintenance is key to preventing brake fade.

- Upgrading components can help prevent brake fade.

Understanding the Basics of F150 Braking Systems

Before we explore the specifics of f150 brake fade causes, it’s helpful to understand how your truck’s braking system works. When you press the brake pedal, you’re starting a chain of events that eventually stops your vehicle. Hydraulic pressure, which is created when you press the brake pedal, activates the brake pads, which clamp down on the rotors. Friction between the pads and rotors slows the wheels down, thus stopping your truck. The braking system includes many parts working together like brake pads, rotors, calipers, brake lines, and the master cylinder. Each part plays a critical role in the braking process, which can be affected by factors like heat, wear, and tear.

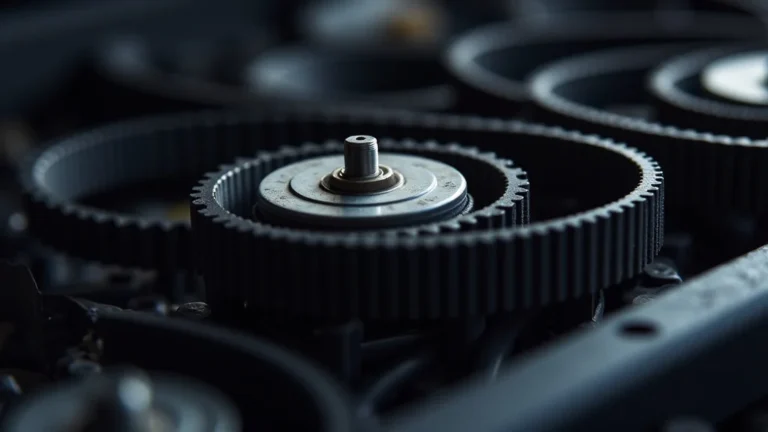

The Role of Brake Pads and Rotors

The brake pads and rotors are the workhorses of your braking system. Brake pads are made of a friction material that presses against the rotors, which are circular metal discs attached to the wheels. This friction converts the kinetic energy of your moving truck into heat. This is why when you brake, your brakes can become hot. The rotors are generally made from cast iron because it can handle high heat and resist wear. The brake pads come in different grades, with some designed for heavy-duty use or performance driving. They are designed to withstand high temperatures and provide the friction needed to stop your truck. The condition of these components greatly influences your ability to stop, making it important to maintain them.

- Brake Pad Composition: Brake pads are made from a mix of materials, like metallic, ceramic, and organic compounds. The choice of material affects braking performance and how long they last.

- Rotor Construction: Rotors, usually made of cast iron, come in solid, vented, or slotted designs. The vented and slotted designs help to dissipate heat faster.

- Wear and Tear: Brake pads wear down over time and must be replaced when they are too thin. Rotors can also wear down or warp due to heat and use.

Different materials offer different friction coefficients and heat resistance. Metallic pads are known for their durability and consistent stopping power, but they can be noisy and harder on rotors. Ceramic pads provide quiet operation, reduced dust, and good performance but can be more expensive. Organic pads provide soft braking, are quieter, and tend to be friendlier to rotors. Therefore, it is important to choose pads that suit your driving needs.

Solid rotors are common on lighter vehicles or for general use. Vented rotors feature internal vanes that circulate air, increasing cooling. Slotted rotors have grooves that channel away gas and dust, further enhancing braking efficiency, especially in wet conditions. The rotor construction impacts the rate at which heat is removed, directly influencing brake fade.

The wear rate of your brake pads depends on your driving habits, the type of pads, and the conditions you drive in. Similarly, rotors can warp due to excessive heat. Warping results in vibrations when braking. Regular inspections and timely replacement of worn parts are important for both safety and brake system longevity. It is critical to regularly inspect your brake pads and rotors for wear, damage, and potential issues.

Hydraulic System Explained

The hydraulic system is the heart of your truck’s braking system. When you press the brake pedal, it pushes brake fluid through the brake lines, which applies pressure to the calipers. The pressure then forces the brake pads against the rotors. The quality and condition of the brake fluid, along with any leaks in the system, are important for optimal braking. A well-maintained hydraulic system ensures responsive and effective braking.

- Brake Fluid Function: Brake fluid is a special liquid designed to transfer the force from your brake pedal to the brakes. It doesn’t compress easily, making it ideal for the job.

- Brake Lines and Hoses: Brake lines are made of metal, while hoses are made of rubber. They carry the brake fluid to the calipers.

- Master Cylinder: The master cylinder is where the brake fluid is stored and pressurized. It’s a vital component in the braking system.

Brake fluid is usually glycol-ether based, and it works by transmitting force from the master cylinder to the wheel cylinders or calipers. This transfer of force enables the brake pads to clamp the rotors. Over time, brake fluid can absorb moisture, which reduces its effectiveness and lowers its boiling point. Therefore, it is important to regularly flush and replace the brake fluid to remove contaminants and maintain performance.

Brake lines are typically made of steel or copper, providing durability and resistance to pressure. Brake hoses, usually made of rubber, connect the brake lines to the calipers. They allow flexibility as the wheels move. Over time, brake hoses can crack or deteriorate, leading to leaks, so they should be checked periodically. Leaks in the hydraulic system can lead to loss of braking power, so keeping your brake lines and hoses in good condition is vital for safe operation.

When you press the brake pedal, the master cylinder activates. It applies pressure to the brake fluid. This is what pushes the fluid through the brake lines. A properly functioning master cylinder is important for providing enough pressure to stop your truck. If the master cylinder fails, it may not generate enough pressure, leading to poor braking performance. Inspecting and maintaining the master cylinder can prevent brake failure.

Common F150 Brake Fade Causes

Brake fade can happen due to many reasons. Usually, it occurs when your brakes get too hot. This heat reduces the friction between the brake pads and rotors. This means your brakes don’t work as well, and it takes longer to stop. Several things contribute to this loss of stopping power, including driving habits and worn-out components.

Overheating of Brake Components

Overheating is the number one cause of brake fade. When you use your brakes a lot, they generate a lot of heat. This is especially true during heavy braking, such as going downhill or in stop-and-go traffic. If the heat gets too high, it can affect the brake pads, rotors, and even the brake fluid. Excessive heat changes the friction properties of the pads, and can lead to reduced braking performance.

- Brake Pad Overheating: Brake pads are made to handle a lot of heat, but if they get too hot, the friction material can start to break down.

- Rotor Overheating: Rotors are designed to dissipate heat, but if they can’t shed heat fast enough, they can warp or become less effective.

- Brake Fluid Boiling: Brake fluid can boil if it gets too hot, which introduces air bubbles into the brake lines.

This is when the braking power decreases. You may feel your brake pedal going soft. High-performance pads are made to handle more heat, but even these pads have a limit. It is important to avoid riding your brakes and allow them time to cool down. Regularly inspect your pads for signs of overheating or wear.

Heat buildup can cause the rotors to change shape, which reduces their ability to provide consistent friction. Warped rotors cause vibrations when braking, further reducing effectiveness. The design of your rotors (vented, slotted) affects how well they can deal with heat. Monitor the condition of your rotors and have them checked or replaced.

Air bubbles can be compressed, so when you press the brake pedal, the force isn’t transferred to the brakes. This reduces braking effectiveness, and makes the pedal feel spongy. Always ensure you use high-quality brake fluid and replace it every couple of years. Over time, brake fluid can absorb moisture, lowering its boiling point and making it more prone to fade.

Driving Habits and Conditions

Your driving style and the conditions you drive in greatly affect your brakes and the likelihood of brake fade. Aggressive driving, such as frequent hard braking, can quickly generate a lot of heat. Long downhill stretches, especially with a heavy load, are hard on brakes and often contribute to heat-related issues. Understanding how driving habits affect your brakes is important for safe driving practices.

- Aggressive Braking: Repeated, hard braking generates excessive heat in a short amount of time.

- Downhill Driving: When driving downhill, the weight of your truck increases the demand on your brakes.

- Heavy Loads: Carrying a heavy load also puts extra strain on your brakes.

This heat can quickly overwhelm the braking system. It can cause brake fade. Try to avoid hard braking, and try to anticipate stops. Also, try to use engine braking when appropriate. This lets the engine help slow the truck down. Remember that gentle braking and a smooth driving style are less hard on your brakes.

If you’re constantly using your brakes to control your speed, they’ll overheat. Try using a lower gear to use the engine to slow your truck down. This reduces the need for continuous braking. When possible, pull over to let the brakes cool down. Plan your route to avoid long or steep downhill sections.

The heavier your truck is, the more work your brakes have to do to stop it. Remember to increase the distance between your truck and the vehicle ahead. This is important to allow extra time for stopping. Consider upgrading your brakes if you frequently carry heavy loads. If you regularly haul cargo, make sure your brakes are up to the task.

Component Wear and Maintenance

Worn-out components and a lack of proper maintenance significantly contribute to brake fade. Worn brake pads lose their effectiveness because there is less friction material. Problems like warped rotors or contaminated brake fluid make the braking system less efficient. Regular inspections and timely repairs are important for preventing brake fade and ensuring optimal braking performance.

- Brake Pad Wear: As brake pads wear down, they lose their ability to effectively grip the rotors.

- Rotor Condition: Warped or damaged rotors reduce the effectiveness of your brakes.

- Brake Fluid Contamination: Contaminated brake fluid can lead to reduced braking performance and brake fade.

Thin pads generate less friction and less stopping power. Regularly check your brake pads for wear. Replace them when they get too thin (usually less than 1/4 inch). Worn brake pads can also damage the rotors, leading to more costly repairs. Following manufacturer guidelines can help prevent premature wear and maintain braking performance.

Warped rotors will not provide consistent contact with the brake pads, which causes vibrations and reduces stopping power. Damage like scoring or excessive rust can also impact braking performance. Inspect your rotors regularly, and replace them if they are warped or damaged. Turning or resurfacing rotors can be a good option when minor issues arise, but sometimes, a complete replacement is better.

Brake fluid can absorb moisture over time, which lowers its boiling point and reduces its effectiveness. Contaminants can also damage other components in the brake system. It is important to flush and replace your brake fluid every couple of years. Make sure to use the right type of brake fluid specified by your truck’s manufacturer. Regular maintenance ensures the brake fluid stays clean and performs as intended.

Symptoms of F150 Brake Fade

Recognizing the symptoms of brake fade is important for driver safety. If you notice any of these signs, you should take action immediately. Being aware of these issues allows you to address the problem before it leads to a serious incident. Regular inspections and prompt maintenance are important for maintaining your truck’s braking performance.

Changes in Braking Performance

Changes in braking performance is usually the first sign that you have a brake issue. If you notice any of these, it’s time to take action. Ignoring these symptoms can lead to dangerous situations and cause more damage. A few things to look out for are changes in brake pedal feel, and a reduction in stopping power.

- Reduced Stopping Power: The most obvious sign of brake fade is that your truck takes longer to stop.

- Spongy Brake Pedal: A spongy or soft brake pedal is another sign of brake fade.

- Vibrations or Pulsations: Vibrations or pulsations in the brake pedal, especially when braking, can indicate rotor problems.

You may need to press harder on the brake pedal or increase the distance to stop safely. If you notice this, it’s important to slow down. Be extra cautious, and get your brakes inspected immediately. Reduced stopping power can be caused by overheated pads, glazed rotors, or other brake issues. Be prepared to react quickly.

This means that when you press the brake pedal, it feels less firm than usual. You may feel like you have to push the pedal further down to get the same braking effect. This feeling comes from the air in the brake lines or boiling brake fluid. Get your brakes checked immediately and replace the brake fluid.

Warped rotors often cause this symptom. The pedal may pulsate or shake when you press the brakes. This will usually make the brakes less effective. If you notice any vibrations, have the rotors inspected and replaced if necessary. It is crucial to address vibrations immediately to prevent more severe damage and ensure safe braking.

Smell and Other Indicators

Besides changes in braking performance, there are other signs that can indicate you have brake fade. Unusual smells or smoke coming from your wheels are not a good sign. If you notice any of these, immediately investigate and address the problem. These indicators can signal serious issues, such as overheating or friction material issues.

- Burning Smell: A burning smell, like burning rubber or a metallic odor, often signals overheated brakes.

- Smoke from Wheels: Smoke coming from your wheels is another warning sign.

- Unusual Noises: Grinding, squealing, or scraping noises when braking can indicate several problems.

This smell is caused by the brake pads or other components overheating and breaking down. Immediately pull over and let your brakes cool down. If the smell persists, get your brakes inspected and addressed. Ignoring this can lead to further damage. Regular inspections and prompt repairs can prevent serious issues.

Smoke suggests excessive heat and friction. This usually indicates that the brakes are severely overheated. Pull over and turn off your engine. Then, allow the brakes to cool down completely before driving again. It is recommended to have your brake system inspected by a qualified mechanic before driving. Do not drive with smoke from your wheels.

These noises can come from worn brake pads, damaged rotors, or other brake issues. These noises should always be addressed. It’s often a sign of metal-to-metal contact, which can quickly damage the rotors. Get your brakes inspected to identify and fix the source of the noise. Address any unusual noises as soon as they appear.

Preventing Brake Fade in Your F150

There are many things you can do to prevent brake fade. Understanding proper driving habits, having routine maintenance, and using high-quality components are key to keeping your brakes working effectively. By adopting these preventive measures, you can improve your safety and prolong the life of your truck’s braking system.

Safe Driving Habits

Adjusting your driving style is one of the most effective ways to prevent brake fade. Driving habits influence the amount of heat and strain placed on your brakes. By adopting defensive driving practices, you can minimize the risk of overheating your brakes and improve your overall safety.

- Avoid Riding the Brakes: Avoid constantly keeping your foot on the brake pedal.

- Use Engine Braking: Engine braking uses the engine to help slow down the truck.

- Maintain a Safe Following Distance: Keeping a safe distance allows you more time to react and brake gently.

This generates heat that can lead to brake fade. Instead, anticipate stops and use a steady braking technique. Reduce your speed well ahead of time to minimize the need for heavy braking. Avoid riding the brakes. Use engine braking. This reduces strain on your brakes and allows them to cool.

This is especially useful when going downhill. It reduces the need to use your brakes constantly, which can prevent overheating. Using a lower gear will increase engine braking. Use engine braking on long downhill stretches. This will take some of the workload off your brakes, and prevent heat buildup.

This reduces the need for sudden, hard braking. A safe following distance allows you to avoid situations that can lead to aggressive braking. Always maintain enough distance between your truck and the vehicle ahead. This is especially important in stop-and-go traffic. Maintain a safe distance to allow for smooth braking and give the brakes time to cool.

Regular Maintenance and Inspections

Regular maintenance is essential for keeping your brakes in top condition and preventing brake fade. Consistent maintenance can identify and fix issues before they become major problems. Regular inspections and timely replacements of worn components are important for maintaining your truck’s braking performance. following manufacturer recommendations will ensure your brakes are reliable and safe.

- Regular Brake Inspections: Regularly inspect your brakes, including the pads, rotors, and calipers.

- Brake Fluid Flush and Replacement: Change your brake fluid every two to three years.

- Prompt Component Replacement: Replace worn components, such as brake pads and rotors, as soon as they show signs of wear.

Check the thickness of the brake pads, look for damage on the rotors, and check for any leaks in the hydraulic system. You can perform these inspections yourself, or have a professional mechanic check them. Many mechanics recommend having your brakes inspected with every oil change. Routine inspections will catch potential issues before they cause brake fade.

Brake fluid absorbs moisture over time, which lowers its boiling point and reduces its effectiveness. Flushing and replacing the fluid gets rid of any contaminants and keeps the hydraulic system working correctly. Refer to your truck’s manual for the recommended fluid type and change intervals. Keeping brake fluid clean prevents brake fade.

Thin brake pads or warped rotors significantly affect braking performance. Regular inspections will help you identify when it’s time to replace them. Ignoring wear and tear will lead to more severe damage. Regularly replacing worn components is essential. This helps to maintain optimal braking performance and prevents potential brake fade.

Upgrading Brake Components

Upgrading your brake components can significantly improve your truck’s braking performance and reduce the risk of brake fade, especially if you often haul heavy loads or do performance driving. Some upgrades provide better heat resistance and braking power, which can help prevent overheating and maintain consistent stopping power. Select the right components to improve safety.

- High-Performance Brake Pads: High-performance brake pads are designed to handle higher temperatures.

- Upgraded Rotors: Upgraded rotors, such as slotted or drilled rotors, help dissipate heat more efficiently.

- Stainless Steel Brake Lines: Stainless steel brake lines reduce the chances of brake fade.

They provide better braking performance. These pads often have a different friction material than standard pads. They resist fading better. Consider high-performance pads if you frequently use your truck for towing or off-road driving. These pads increase braking power and decrease the risk of brake fade. Choose pads rated for your truck and driving needs.

These features improve the cooling and reduce the risk of warping. Slotted rotors channel away brake dust and gases. Drilled rotors increase the surface area for heat dissipation. These upgrades can greatly improve braking performance and reduce the chances of brake fade. These options are perfect for towing.

Stainless steel brake lines are more resistant to swelling under pressure compared to standard rubber lines. This improvement provides a firmer pedal feel and more efficient braking. They also are more durable, reducing the risk of leaks. Upgrading to stainless steel brake lines offers consistent and reliable braking, especially under challenging conditions.

| Component | Standard Component | Upgraded Component | Benefits |

|---|---|---|---|

| Brake Pads | Standard Organic/Semi-Metallic | High-Performance Ceramic/Metallic | Better heat resistance, improved stopping power |

| Rotors | Solid Rotors | Slotted/Drilled Rotors | Improved heat dissipation, reduced fade |

| Brake Lines | Rubber Brake Lines | Stainless Steel Braided Lines | Firmer pedal feel, improved durability |

Frequently Asked Questions

Question: What is brake fade?

Answer: Brake fade is the loss of braking effectiveness due to heat buildup, making it harder to stop your truck.

Question: What causes brake fade in my F150?

Answer: Overheating of brake components, aggressive driving, long downhill stretches, heavy loads, and worn parts.

Question: How can I prevent brake fade?

Answer: Drive with care, use engine braking, and maintain your brakes with regular inspections and parts replacement.

Question: What should I do if my brakes start to fade?

Answer: Pull over and let your brakes cool. Check your braking system before resuming driving.

Question: Are there any upgrades to reduce brake fade?

Answer: Yes, upgrading to high-performance brake pads, slotted/drilled rotors, and stainless-steel brake lines.

Final Thoughts

Dealing with f150 brake fade causes can be confusing, but now you know the main reasons it happens. We’ve explored everything from overheating to driving habits, giving you the knowledge to handle this common problem. By learning how your brakes function, understanding the warning signs, and following a few basic steps, you can prevent brake fade and keep yourself safe on the road. Remember, regular maintenance is important. Pay attention to your brakes, drive carefully, and get your truck checked regularly. Doing these things can prevent a lot of problems and make sure you can always stop safely. With a little effort, you can maintain your truck’s brakes and make every drive a safer one.