F150 Fuel Pressure Symptoms Diagnosing Common Problems

If you’re an F150 owner, you might sometimes worry about f150 fuel pressure symptoms. It can be a little tricky at first! Many people struggle because fuel systems are complicated. But don’t worry, it’s easier to fix than you think. This post will give you a simple, step-by-step guide to recognizing and solving these problems. We’ll explore what to look for and the most common causes, so you can keep your truck running smoothly. Let’s get started and uncover the signs and causes!

Key Takeaways

- Learn to identify common f150 fuel pressure symptoms in your vehicle.

- Discover the key components that affect fuel pressure.

- Understand how to diagnose fuel pressure issues using simple tools.

- Find out how to safely repair or replace faulty fuel system parts.

- Get practical advice on preventing future fuel pressure problems.

- Gain confidence in your ability to address fuel system concerns.

Recognizing F150 Fuel Pressure Problems

The first step in addressing any issue with your F150 is recognizing the signs. Several symptoms can indicate a problem with your fuel pressure. These symptoms often start subtly, and worsen over time if left unchecked. Knowing these early warning signs is important to prevent major problems and expensive repairs. Let’s explore some of the most common f150 fuel pressure symptoms and what they mean for your truck’s performance and longevity. Being aware of the early indicators will make it easier to maintain your vehicle.

Common Symptoms

One of the easiest ways to spot an issue is by paying close attention to your vehicle’s behavior. Different symptoms can pop up based on the severity and nature of the fuel pressure problem. Some indicators are very obvious, while others may require a more observant eye or ear. Each symptom provides a clue, and collecting them together can help you find the source of the issue. Let’s dig deeper into the common signs, so you can catch these problems before they become bigger headaches.

- Difficulty Starting: A vehicle struggling to start is one of the most common issues. If your engine cranks but won’t fire up, or takes several attempts to start, low fuel pressure could be the culprit. This happens because there’s not enough fuel getting to the engine to allow the combustion process to start.

- Rough Idling: Does your truck idle roughly, shaking or misfiring when it’s just sitting there? This is another symptom. Low or inconsistent fuel pressure can mess with the engine’s air-fuel mixture, making it run poorly. This can be felt as shaking or irregular operation when your truck is stopped.

- Loss of Power or Hesitation: If your F150 doesn’t accelerate as it should, or has a hesitation when you press the gas pedal, fuel pressure could be to blame. This happens because the engine isn’t getting enough fuel during acceleration or while under load. The engine needs a steady supply of fuel to perform properly, and a shortage can affect its ability to deliver.

- Reduced Fuel Efficiency: Do you notice that you are visiting the gas station more often? Reduced fuel efficiency can also be an indication. When the engine’s fuel injectors are not properly delivering fuel, this can lead to inefficient fuel use. This can result in increased fuel consumption and higher operating costs.

If your engine needs multiple attempts to fire up, it could point toward a fuel pressure problem. In a healthy engine, the fuel injectors are able to supply the necessary fuel for combustion from the first crank. You should address this before it causes starting problems.

Rough idling is often linked to an improper air-fuel mixture, which is partly caused by inconsistent fuel pressure. The issue can worsen engine vibration and even cause the engine to stall. Addressing this problem quickly can prevent more damage.

A loss of power or hesitation might make your truck feel sluggish. This is often because the engine can’t deliver enough power to meet the driver’s demand. Early detection and repair can often restore optimal performance and prevent further issues.

Poor fuel economy is not only bad for your wallet but can also signal internal issues. Your vehicle’s engine requires the correct amount of fuel to run efficiently, and any imbalances can affect fuel economy. Monitoring your fuel usage over time will help you notice this symptom.

Diagnosing Early Signs

Finding out the source of the problem is important before you start trying to fix it. Knowing how to observe your vehicle and perform basic checks can help you figure out if fuel pressure is a problem. You can start by examining the symptoms you are seeing, and then proceed with a methodical method to locate the root cause. This information will help you narrow down the issue and prepare for troubleshooting.

- Check Engine Light: The check engine light is your first signal. If the light comes on, it could mean there’s a problem with your fuel system. Using an OBD-II scanner can provide trouble codes that relate to fuel pressure. The codes will help focus on the source of the problem.

- Listen for the Fuel Pump: Turn the key to the “on” position without starting the engine. You should hear the fuel pump run for a few seconds. If you don’t hear anything, the fuel pump may be bad. The fuel pump provides the initial pressure that delivers fuel to your engine.

- Visual Inspection: Inspect the fuel lines and connections for leaks or damage. Look for any signs of fuel on the ground or around the fuel components. Leaks are a clear indication of fuel pressure issues and should be addressed right away.

An illuminated check engine light is often the first indicator of problems. By checking it as soon as the light turns on, you can catch issues before they escalate. With the right tools, you may be able to read trouble codes related to fuel pressure.

The fuel pump usually runs briefly when you start the car. You can hear it hum near the fuel tank. This short test can tell you if the pump is working. No sound could be an early indicator of a potential issue.

Visually checking your fuel system for leaks can catch problems early. Check all the fuel lines, connections, and components. Even a tiny leak will cause problems and should be fixed before it leads to other issues.

The Main Fuel System Components

Knowing the key parts of your F150’s fuel system is key to knowing where problems can occur. From the fuel tank to the engine, many parts work together to supply your engine with the necessary fuel. Understanding what each component does and how it affects fuel pressure will help you pinpoint potential problems. Let’s look at the crucial parts, to help you better understand your truck’s fuel system.

Fuel Pump

The fuel pump is the heart of the fuel system. It pulls fuel from the tank and sends it to the engine under pressure. Located inside the fuel tank, the pump makes sure that a continuous supply of fuel is available. When the fuel pump fails, your truck may not start or run properly.

- Location and Function: The fuel pump is typically mounted inside the fuel tank. Its primary job is to draw fuel from the tank and push it through the fuel lines to the engine. The fuel pump is essential for maintaining constant fuel pressure.

- Common Issues: Fuel pumps can fail for many reasons, including wear and tear, electrical problems, and contamination. Symptoms of a failing fuel pump include starting difficulties, loss of power, and, of course, no start. The pump can also start to make noises.

- Replacement or Repair: Replacing a fuel pump typically requires specialized tools, but you can do it yourself. It involves removing the fuel tank and installing a new pump. The cost for repair may vary depending on the model and the labor costs of the shop.

The fuel pump is placed inside the tank to keep it cool and quiet. By keeping a steady fuel flow, the fuel pump ensures that the engine gets the fuel it requires for correct operation. Without a functional fuel pump, the engine won’t get any fuel.

A failing fuel pump can cause many performance problems. Regular maintenance, such as changing the fuel filter, can extend the life of your fuel pump. Pay attention to how the engine performs, so you can solve pump problems before they leave you stranded.

When the fuel pump is damaged, it needs to be

Fuel Filter

The fuel filter keeps impurities out of the fuel. It prevents contaminants like dirt, rust, and other debris from entering the fuel system and damaging the fuel pump and injectors. Regularly changing the fuel filter is crucial for the life of your engine. A dirty or clogged fuel filter can significantly reduce fuel pressure and cause performance issues.

- Location and Function: The fuel filter is normally located along the fuel line, between the fuel tank and the engine. Its primary job is to filter the fuel, removing any contaminants before they reach the engine. This filtration is important for the engine’s performance.

- Common Issues: The fuel filter can become clogged over time, especially if the truck is driven in dirty environments or if the fuel quality is poor. A clogged filter will reduce the amount of fuel that can flow to the engine. The engine will not function well when this occurs.

-

Replacing the fuel filter can be done with basic tools. Always use a new filter from a trusted brand. Regularly changing the filter will keep your fuel system in great shape.

The fuel filter’s positioning allows it to catch impurities before they enter the engine. Maintaining a clean fuel supply helps prevent problems with the fuel pump and injectors. Regular maintenance is necessary to keep the filter working well.

A clogged fuel filter restricts fuel flow, causing reduced engine power and rough running. The filter needs to be changed before the engine’s performance is affected. Replacement intervals are typically outlined in your truck’s owner’s manual.

Fuel Injectors

Fuel injectors spray fuel into the engine cylinders. They are controlled electronically, ensuring the correct amount of fuel is delivered for optimal performance. Faulty injectors can lead to many performance issues, including misfires, poor fuel economy, and rough idling. Keeping your fuel injectors in good shape can improve engine efficiency.

- Location and Function: Fuel injectors are mounted inside the intake manifold or directly into the engine cylinders. They spray fuel in a fine mist, combining with air to create a combustible mixture. Precise injection improves engine performance and efficiency.

- Common Issues: Fuel injectors can become clogged or fail due to debris, bad fuel, or electrical issues. This will impact the engine’s performance and cause problems such as misfires and poor fuel economy. Diagnosing injector problems requires specialized tools.

- Testing and Cleaning: Fuel injectors can be tested for flow rate and spray pattern. Cleaning them can sometimes restore performance. Various methods can be used, including ultrasonic cleaning. In addition, you can use fuel system cleaners.

Fuel injectors provide fuel directly into the cylinders. Their exact design controls the amount and timing of fuel delivery, which directly impacts the engine’s performance. Consistent injector operation is key to a smooth engine operation.

The most common issues for fuel injectors include clogging, which restricts fuel flow, and electrical failures, which can interrupt fuel delivery. Keeping up with regular maintenance, like using fuel additives, can help prevent issues. If injectors get too bad, they may have to be replaced.

Cleaning or replacing injectors can restore engine performance. Testing allows you to determine if the injectors are working correctly. Maintaining fuel injectors will improve your engine performance and fuel efficiency.

Diagnosing Fuel Pressure: Tools and Techniques

Diagnosing fuel pressure problems requires certain tools and knowledge. Getting the right gear will help you identify the source of the problem correctly. From pressure gauges to diagnostic scanners, having the correct equipment will allow you to do a thorough diagnosis. Let’s see some basic diagnostic techniques to figure out fuel pressure problems on your F150. Being able to do some tests yourself will save you money.

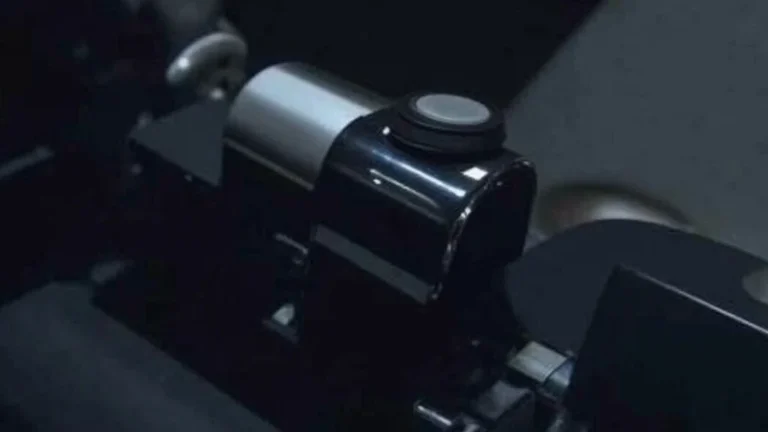

Using a Fuel Pressure Gauge

A fuel pressure gauge is the most important tool for checking fuel pressure. It connects to the fuel rail, letting you know the pressure. This is a very useful way to determine if your fuel pump and fuel system are working correctly. It is a quick and simple way to detect potential problems. Here is how to use a fuel pressure gauge.

- Connecting the Gauge: The gauge connects to the fuel rail using the Schrader valve, usually found on the fuel rail. Relieve the fuel system pressure before connecting the gauge to avoid fuel spray. Make sure to connect it securely to get an accurate reading.

- Reading the Gauge: After connecting, start the engine and observe the fuel pressure reading. The pressure should be in the range specified by the manufacturer. Check your owner’s manual to find the right fuel pressure for your F150.

- Interpreting the Readings: If the pressure is too low, it may indicate a weak fuel pump or a clogged fuel filter. If it’s too high, it might be a problem with the fuel pressure regulator. Fluctuations can signal an inconsistent fuel supply.

To connect the gauge, you’ll need the appropriate adapter. The Schrader valve is like a tire valve, and it will allow you to connect the gauge. Make sure the connection is secure to avoid any fuel leaks.

Start the engine to take an accurate pressure reading. Watch for pressure changes to look for any signs of a problem. If the pressure doesn’t fall within the set range, it indicates a fuel pressure problem.

The gauge reading will indicate the source of any issues. Low pressure indicates a pump or filter problem. The readings will tell you if the fuel system is working correctly. It gives you the information you need to fix the issue.

Using an OBD-II Scanner

An OBD-II scanner can give you important details about your truck’s performance and help you diagnose fuel pressure problems. This tool can display real-time data, and retrieve any trouble codes. The scanner can give you more information about what’s going on with your truck. Understanding how to use an OBD-II scanner can greatly help you in diagnosing f150 fuel pressure symptoms.

- Connecting the Scanner: The OBD-II port is usually located under the dashboard on the driver’s side. Plug the scanner into this port, and turn the ignition key to the “on” position without starting the engine. Follow the scanner’s prompts.

- Reading Trouble Codes: Use the scanner to read any trouble codes. These codes will pinpoint possible fuel system problems. For instance, codes related to the fuel system may suggest low fuel pressure or fuel injector issues.

- Viewing Live Data: The scanner can also display live data, including fuel pressure readings in real-time. This can show how fuel pressure behaves under different conditions, such as acceleration or idling. You can find out if the pressure is constant.

The OBD-II port gives your scanner access to your truck’s computer. It’s normally located for easy access. Follow the scanner’s prompts to make a connection. This will help you get accurate data.

The scanner will display any active or stored codes. These codes are important. Each code has specific meanings, and they’ll help you pinpoint the issue. Look up the code online or in the scanner’s manual to get the details.

Real-time data can help detect problems that come and go. When you are driving, you can monitor the fuel pressure and check for any fluctuations. This allows you to evaluate your engine’s performance and determine if your fuel system is keeping up.

Other Helpful Checks

In addition to using a fuel pressure gauge and OBD-II scanner, you can also perform other checks. These additional checks may help you identify the source of the fuel pressure problems. You can check the fuel filter and fuel lines for any damage. Here are some extra checks.

- Fuel Line Inspection: Carefully inspect the fuel lines for leaks, cracks, or any signs of damage. Any damage can impact fuel pressure and cause fuel leaks. Be sure to check all connections, including fittings, to make sure everything is connected correctly.

- Fuel Filter Check: Examine the fuel filter for any signs of clogging or contamination. A clogged filter will restrict fuel flow, leading to low fuel pressure. Change the fuel filter if it looks dirty or has too much build up.

- Fuel Pressure Regulator Check: Verify the function of the fuel pressure regulator. This component controls fuel pressure, so a problem with it can lead to incorrect pressure. You can test it by pinching off the return line.

Check the fuel lines. They can get damaged from road debris or corrosion. Leaks can cause loss of pressure and fuel economy problems. Look for any wet spots, and repair or replace any damaged parts.

If the fuel filter is damaged or clogged, fuel flow can be limited. Replace it if needed. Replacing the filter at recommended intervals is a good way to maintain your fuel system.

The fuel pressure regulator’s job is to maintain the correct fuel pressure. Testing this component will determine if it is working correctly. A malfunctioning regulator can affect fuel delivery, and may require replacing.

Troubleshooting and Solutions

After you have figured out the problem, it’s time to find a solution. The solution depends on what you have discovered through your diagnostic work. You might need to change a component or simply repair a fuel line. Here’s a look at common issues and what you can do about them.

Fuel Pump Issues and Solutions

When you have determined that your fuel pump is defective, it will probably need to be replaced. Replacing it involves some steps. Knowing how to do this correctly is important for getting the truck running correctly. Here are the steps for replacing your fuel pump.

- Fuel Pump Replacement: If the fuel pump is failing, you will need to replace it. Begin by removing the fuel tank and disconnecting the fuel lines. Then, carefully take out the old pump from the tank. The replacement may involve some specialized tools.

- Fuel Pump Relay: Make sure the fuel pump relay is working correctly. It is essential for the electrical system. You should check the relay to make sure it is providing power to the fuel pump. If the relay is bad, it will not power the fuel pump.

- Wiring Issues: Check the wiring to the fuel pump for damage, corrosion, or loose connections. Bad wiring can cut off power to the fuel pump. Take a close look at the connectors and wiring harnesses, and fix or replace anything that is broken.

When you

Testing the fuel pump relay is easy to do. You can swap it with another relay to determine whether the problem is the relay itself. If it is, changing the relay is an easy fix. If the fuel pump does not run, the relay may be the problem.

Damaged wires or connections can prevent your fuel pump from running. Inspect the wiring to find any problems. Fix any broken wires, and make sure that the connections are tight. Maintaining the electrical system will help keep the fuel pump operating correctly.

Fuel Filter Problems and Repair

A clogged fuel filter is a very common issue, and the solution is to replace it. Here is the process for replacing it. It’s a simple, but crucial task for maintaining fuel pressure.

- Fuel Filter

Always release the fuel pressure by removing the fuel pump fuse, and running the engine. Then, disconnect the fuel lines and replace the filter. Be sure to align the filter correctly. Make certain the connections are secure.

- Choosing the Right Fuel Filter: Make sure you buy a fuel filter that is designed to work with your truck’s model and year. Using the correct fuel filter will ensure that it works as it should. Using the wrong filter will affect the fuel system.

- Fuel Line Cleaning: If the fuel lines have contamination, you may want to clean them. Use a fuel system cleaner to remove any remaining debris. Prevent debris from entering the fuel system during maintenance procedures.

There are different types of fuel filters available. Make sure you use the right type. It’s usually easy to find the correct filter. Your owner’s manual will give you the right filter type. Choosing the correct filter is important.

Over time, fuel lines can develop build up. A fuel system cleaner will remove any contamination. You can get fuel system cleaner from any auto parts store. Keeping your fuel lines clean will help with fuel flow.

Fuel Injector Cleaning or Replacement

Fuel injectors can sometimes be cleaned to fix performance problems, or they may need to be replaced. Keeping your injectors working well will ensure the best possible engine operation. Here are the steps involved.

- Fuel Injector Cleaning: Fuel injectors can sometimes be cleaned to remove deposits. You can use an injector cleaning tool or a fuel additive. However, cleaning alone might not fix severe issues. Cleaning your fuel injectors will help with fuel flow.

- Fuel Injector Replacement: If the injectors are badly clogged or damaged, you’ll need to replace them. This usually involves removing the fuel rail and replacing the injectors one at a time. This process may require some specific tools.

- Professional Help: If you are not comfortable working on your fuel system, it is advisable to get help from a professional. Mechanics have the tools and expertise to find and fix fuel system problems. They can also ensure that all repairs are done correctly.

Cleaning your fuel injectors is a routine job. You can do this yourself by following the instructions on the product. Periodic cleaning will help injectors keep working well. This will improve your engine performance.

Replacing the fuel injectors will return your engine to great performance. Using a high quality replacement will help you get the best outcome. Ensure that you have the correct equipment and know how to use it safely.

Fuel systems can be complex, and getting help from a professional mechanic can be a good idea. They have experience dealing with these systems. Having a professional handle the repairs will protect your investment.

Preventing Fuel Pressure Problems

Preventing fuel pressure problems requires regular maintenance. These practices will prevent issues from appearing in the first place. You will need to take steps to protect your fuel system. Here are some steps you can take to keep fuel pressure problems from happening.

Regular Maintenance

Regular maintenance is a great way to prevent problems with your fuel system. Following a maintenance schedule will keep the fuel system working correctly. This reduces the chance of problems arising, and it will keep your F150 running well. Always follow the manufacturer’s recommendations for vehicle maintenance.

- Fuel Filter Replacement Schedule: Follow the manufacturer’s instructions for the fuel filter. Replace the filter at regular intervals. This helps prevent contaminants from building up. Changing the filter will improve fuel flow.

- Fuel System Cleaning: Use fuel system cleaners on a regular basis. Fuel system cleaners will help remove deposits and improve injector performance. Cleaners will help maintain clean fuel injectors and lines.

- Professional Inspections: Have a professional inspection of your fuel system from time to time. This can identify problems you may not have noticed. A mechanic can spot potential problems early.

The fuel filter traps impurities, so it needs to be changed. Replace it at the recommended mileage interval, or as recommended in your owner’s manual. A good maintenance schedule will save money and help the engine run well.

Fuel system cleaners may remove any impurities. These additives will also assist in keeping the fuel system clean. Adding a fuel system cleaner will reduce the need for more costly maintenance. You may save money by maintaining the fuel system.

A professional inspection can identify issues before they cause significant damage. These inspections are a valuable step to keeping your vehicle running smoothly. A mechanic will check all the parts and connections, and catch any problems early.

Fuel Quality and Habits

The type of fuel you use and your driving habits can influence the lifespan of your fuel system. The fuel quality and how you drive play a big role in your vehicle’s long-term performance. You can use the tips below to make sure your truck runs smoothly.

- Use Quality Fuel: Always choose high-quality fuel. Try to find name-brand gasoline from a reliable station. This will reduce the chance of contaminants from entering your fuel system. This can affect the fuel injectors and lines.

- Avoid Running Low on Fuel: Running your fuel tank low on fuel can cause the fuel pump to overheat. The fuel pump relies on fuel for cooling. Keeping a good amount of fuel in your tank helps protect the fuel pump.

- Driving Habits: Drive smoothly and avoid harsh acceleration and braking. Aggressive driving can stress your fuel system. Moderate driving will reduce wear and tear on all parts of the engine.

Premium fuel has fewer contaminants and additives. Using a good fuel reduces the chances of damage, and protects the fuel system. Avoid using fuel that is old, or from an unreliable source.

The fuel in your tank cools the fuel pump. A low tank level can cause the pump to overheat. Avoid letting the fuel level drop too low, and this will help maintain your pump. This will extend the life of your fuel pump.

Driving too fast and making sharp turns can make your fuel system work harder. By driving with a lighter touch, you can make your fuel system last. Avoiding hard driving will help extend the life of the engine.

Storage and Long-Term Care

If you plan to store your F150 for an extended period, you will need to prepare the fuel system to avoid problems when you restart it. Appropriate storage will reduce the chance of damage to your fuel system. Let’s look at some important steps to prevent issues during extended storage.

- Fuel Stabilizer: Use fuel stabilizer before storing your truck. This will prevent the fuel from breaking down. Adding fuel stabilizer will protect the fuel lines and injectors. You can prevent issues like fuel degradation.

- Empty or Fill the Tank: You can choose to either empty the fuel tank or fill it up completely. If you choose to empty it, the fuel system should be thoroughly cleaned. If you opt to fill it, add a fuel stabilizer. This choice depends on your preference.

- Regular Checks: If you plan to store your truck for a long time, check it regularly. Operate the engine every couple of weeks to circulate the fuel and lubricate the components. You may also want to inspect the fuel lines.

Fuel stabilizer is a chemical additive that helps keep the fuel from degrading. Fuel stabilizer keeps the fuel fresh and protects the fuel system parts. Make sure to add it at the correct concentration to the fuel tank before you store the vehicle.

The fuel tank may be emptied to prevent fuel degradation. You may want to fill it up completely to prevent condensation. Decide which option suits your needs. Either way, you will need to take steps to protect the fuel system.

Regular maintenance will help prevent a variety of issues. Starting the engine occasionally will help maintain the fuel system’s parts. This is also a good time to check your fuel system for any leaks. These steps will help you preserve your vehicle.

Frequently Asked Questions

Question: What are the main symptoms of a fuel pump failing?

Answer: The primary signs of a failing fuel pump are difficulty starting the engine, loss of power, and rough idling.

Question: Can a clogged fuel filter cause performance issues?

Answer: Yes, a clogged fuel filter will restrict fuel flow, which can lead to a loss of power and reduced fuel efficiency.

Question: How often should I replace the fuel filter in my F150?

Answer: Follow the recommended replacement intervals found in your owner’s manual, or every 30,000 to 50,000 miles.

Question: What tools do I need to test fuel pressure?

Answer: The most important tool is a fuel pressure gauge, which connects to the fuel rail to provide a pressure reading.

Question: Is it safe to work on my fuel system myself?

Answer: Work on your fuel system with caution. Always release fuel pressure before doing any work. Use safety gear, and make sure that you know what you are doing.

Final Thoughts

Identifying and solving f150 fuel pressure symptoms doesn’t have to be complicated. By carefully observing your truck for any unusual behavior, and recognizing common signs like starting trouble, loss of power, or poor fuel economy, you can catch problems early. Knowing the role of components, like the fuel pump, filter, and injectors, helps you understand where the issue might lie. If your truck starts to show signs of trouble, try using a fuel pressure gauge and a diagnostic scanner to narrow down the source of the problem. Simple maintenance steps, like replacing the fuel filter, and using quality fuel will help keep your F150 in great shape. By taking these steps, you can prevent serious problems. When you maintain your truck, it will keep you on the road and running well for a long time.