What Causes F150 Hesitation at Low RPM Explained Simply

If you’re wondering what causes f150 hesitation at low rpm, you’re not alone! This is a common issue for many F150 owners, especially if you’re just getting started with vehicle maintenance. It can seem confusing, but don’t worry. This post will break down the most likely causes of hesitation at low RPM and explain them in a way that’s easy to follow. We’ll go step by step, so you can diagnose and hopefully fix the issue yourself. Let’s get started!

Key Takeaways

- Hesitation at low RPM in an F150 can stem from various sources, mainly relating to the engine’s ability to efficiently receive fuel and spark.

- Fuel system issues, like a clogged fuel filter or faulty fuel pump, often disrupt the fuel supply, causing hesitation.

- Problems with the ignition system, such as worn spark plugs or a malfunctioning coil pack, can lead to misfires and hesitation.

- Sensor malfunctions, especially in the mass airflow sensor (MAF) or oxygen sensors, can provide incorrect data to the engine’s computer.

- Regular maintenance, including replacing filters and checking spark plugs, is vital for preventing low-RPM hesitation.

- Diagnosing the issue involves careful inspection of several components and, in some cases, the use of a diagnostic tool.

Common Causes of Engine Hesitation

Engine hesitation at low RPM can be frustrating. It’s that moment when you press the gas, and the engine stumbles before it gets going. It often feels like the vehicle is struggling to get enough power, especially when you’re accelerating from a stop or at slow speeds. Many things can contribute to this, but most of them fall into a few categories: fuel delivery, the ignition system, or the engine’s sensors. We’ll explore each of these areas, explaining the key components and how they can affect your F150’s performance.

Fuel System Issues

The fuel system is the lifeline of your engine. It’s responsible for getting the right amount of fuel to the engine cylinders so your truck can run smoothly. Any issue with this process can cause all sorts of problems. These problems often manifest as the engine hesitating at low RPM. When the fuel supply is inadequate, the engine struggles to provide the necessary power, resulting in a lag when accelerating or a general lack of responsiveness. Let’s look at some common fuel system issues that can cause this.

- Fuel Filter: The fuel filter is there to keep dirt and debris from getting into your engine. Over time, it can get clogged. When the filter is clogged, it can’t deliver enough fuel to the engine when you ask for more power. The engine will hesitate, especially at lower RPM when it’s most sensitive to fuel flow. Replacing your fuel filter regularly is a good way to keep your engine happy.

- Fuel Pump: The fuel pump pushes fuel from the gas tank to the engine. If the fuel pump is failing, it might not provide enough fuel pressure, which can cause hesitation. The fuel pump’s job is to ensure that fuel reaches the engine under sufficient pressure, even during acceleration. If the pump weakens or malfunctions, the engine might not get the fuel it needs quickly, causing hesitation.

- Fuel Injectors: Fuel injectors spray fuel into the engine cylinders. If they are clogged or faulty, they might not deliver fuel properly. Injectors are precision instruments that spray fuel into the engine cylinders. The injectors spray the correct amount of fuel at the right time. When injectors become clogged or begin to fail, the engine’s performance suffers. Clogged injectors can lead to an uneven fuel spray pattern, which causes misfires, hesitation, and reduced power.

A fuel filter’s function is very important to prevent contaminants from reaching the engine. If the filter becomes restricted, the engine may not receive the fuel it needs. Regular replacement, usually every 15,000-30,000 miles, ensures optimal fuel flow and engine performance. Dirty filters can cause the engine to struggle, reducing efficiency and possibly damaging the fuel pump over time.

Fuel pump failure often occurs gradually, with the engine’s performance declining over time. When a fuel pump struggles, it can cause the engine to misfire or even stall. The correct fuel pressure is vital for proper engine operation. Checking the fuel pressure with a gauge is a simple test that can quickly show if the pump is working well.

The spray pattern of the fuel injectors is critical. A bad spray pattern means that fuel may not burn completely, affecting engine performance. Modern fuel injectors can become clogged due to dirt, debris, or fuel additives. Cleaning or replacing the injectors can restore optimal engine performance. Regular maintenance, including the use of fuel injector cleaners, can help prevent injector issues.

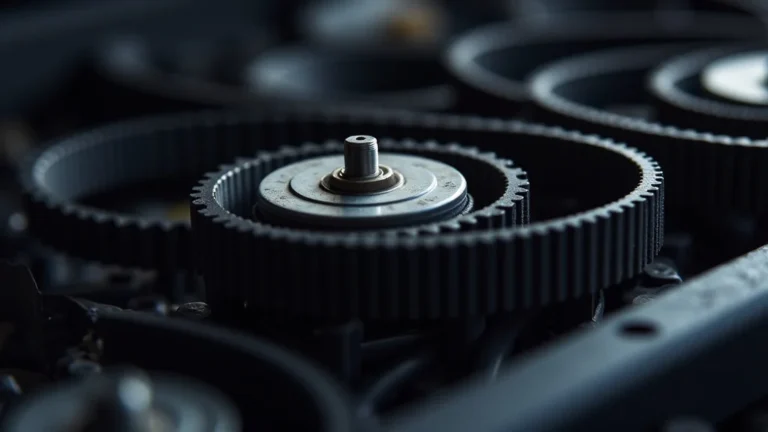

Ignition System Problems

The ignition system is responsible for creating the spark that ignites the fuel in your engine cylinders. If the ignition system isn’t working correctly, the engine can experience misfires, which can lead to hesitation and poor performance. Many components are involved in this process, and even a single faulty component can cause issues. We’ll explore some of the most common ignition problems that can lead to hesitation. Each of these components plays a key role in the precise timing and delivery of the spark needed for efficient combustion.

- Spark Plugs: Spark plugs create the spark that ignites the fuel-air mixture in the engine cylinders. Worn or fouled spark plugs can misfire, leading to hesitation. Spark plugs are a critical part of the ignition system. The plugs are designed to generate a spark that ignites the air-fuel mixture. Over time, they wear out or get fouled by deposits from the combustion process.

- Ignition Coils: Ignition coils provide the high voltage needed to create the spark at the spark plugs. Faulty coils can cause misfires and hesitation. The ignition coil converts low-voltage power into the high-voltage electricity needed for the spark plugs to ignite the fuel mixture. When an ignition coil fails, it can’t deliver the necessary spark. This leads to misfires, especially at low RPM when the engine is under load.

- Spark Plug Wires: If your F150 has spark plug wires, they carry the high voltage from the ignition coil to the spark plugs. Damaged wires can leak voltage, causing misfires. Spark plug wires are vital for the proper function of the ignition system. The wires transport the high-voltage electricity from the ignition coil to the spark plugs. They must be in good condition to deliver the electrical energy efficiently.

The performance of your engine is directly affected by the spark plug’s condition. Worn plugs have a weaker spark, which causes misfires. This results in reduced power, rough idling, and hesitation, especially when the engine is cold or at low RPM. Replacing spark plugs at the recommended intervals ensures reliable engine performance. Check your owner’s manual for replacement intervals; usually, it’s every 30,000 to 100,000 miles, depending on the plug type.

A single faulty coil can cause the engine to run poorly. One symptom of a bad coil is the engine missing or hesitating. The driver might experience a loss of power or notice the engine running roughly. Modern engines often have individual coils for each cylinder. This makes it easier to diagnose which coil is faulty. Replacing the faulty coil fixes the issue. If you’re experiencing a misfire or hesitation, it’s best to check the ignition coils to make sure they’re working.

If the wires are damaged, the energy leaks. This results in weak sparks, misfires, and hesitation. The engine’s performance declines. Regular inspection of the spark plug wires can prevent problems. Checking for cracks, fraying, or any signs of wear is essential. Replacing faulty wires can improve engine performance and fuel efficiency. It’s a quick fix that often resolves hesitation problems.

Sensor Malfunctions

Your engine has many sensors that provide important information to the engine control unit (ECU). These sensors help the ECU adjust fuel and ignition timing for optimal performance. If any of these sensors malfunction, the engine may not get the right amount of fuel or spark, which causes hesitation. The engine’s ECU relies on a variety of sensors to monitor the engine’s operations. If any of these sensors fail or send incorrect signals, the ECU may not make the proper adjustments. Let’s look at a few sensors that can cause these problems.

- Mass Airflow Sensor (MAF): The MAF sensor measures the amount of air entering the engine. If it’s faulty, the ECU might not deliver the correct amount of fuel, leading to hesitation. The MAF sensor is a key component for calculating the correct air-fuel mixture. It’s usually located between the air filter and the throttle body. The MAF measures the mass of air flowing into the engine. This information is sent to the ECU, which adjusts the fuel injectors to deliver the right amount of fuel.

- Oxygen Sensors: Oxygen sensors measure the amount of oxygen in the exhaust. They help the ECU adjust the air-fuel mixture. Faulty oxygen sensors can cause the engine to run inefficiently, leading to hesitation. These sensors are vital for emissions control and engine performance. The ECU relies on the data from the oxygen sensors to ensure the air-fuel mixture is optimal. This is necessary for a clean burn and efficient fuel use.

- Throttle Position Sensor (TPS): The TPS tells the ECU how far open the throttle is. A bad TPS can cause hesitation when accelerating. This sensor’s job is to tell the ECU the exact position of the throttle valve. The ECU uses this data to manage fuel delivery and ignition timing. When the TPS malfunctions, it may send incorrect information to the ECU. This can lead to erratic engine behavior, especially during acceleration.

A bad MAF sensor can cause the engine to run too rich or too lean, leading to hesitation, rough idling, and reduced power. If the MAF sensor is sending the wrong information, the ECU will miscalculate the fuel requirements. This is why it’s important to keep the MAF clean. Cleaning the MAF sensor with a special cleaner is often a good first step. If cleaning doesn’t work, then you should consider replacing it.

If the oxygen sensors fail or provide incorrect readings, the ECU may not be able to adjust the fuel mixture correctly. This can lead to various problems, including hesitation, poor fuel economy, and higher emissions. You can find oxygen sensors in the exhaust system before and after the catalytic converter. When a sensor goes bad, it often triggers the check engine light. You should replace the faulty sensors to resolve the issue.

If the TPS gives the wrong information, the engine might not respond smoothly to your commands. This can manifest as hesitation when you step on the gas. The engine may surge or stumble. A bad TPS might cause the engine to hesitate during acceleration or deceleration. Replacing the TPS can often resolve these issues, restoring smooth engine operation and responsiveness.

More Considerations When Diagnosing F150 Hesitation at Low RPM

Diagnosing what causes F150 hesitation at low RPM requires a careful approach. First, it’s very important to note that the issue can come from several different places. You can’t just assume one thing is the cause. You must take a logical approach. Start by checking for obvious signs, such as a check engine light, unusual noises, or specific driving conditions where the problem occurs. Using a diagnostic tool to read any stored trouble codes is a great starting point, too.

- Check Engine Light: The check engine light is your first indicator. If it’s on, the vehicle’s computer has detected a problem and stored a trouble code. This code will give you an idea of what’s wrong. The check engine light can tell you if there is an issue with the engine’s emissions. The light comes on when the vehicle’s computer detects a problem. When the light turns on, it provides useful clues about the vehicle’s condition.

- Use a Diagnostic Tool: A diagnostic tool can read codes, and it can also show you live data from the engine sensors. This data is very useful. It can show you how the engine is running in real-time. A diagnostic tool helps you explore the engine’s performance. These tools can display real-time data, which is useful when diagnosing engine issues.

- Visual Inspection: A close visual inspection of the engine and related components can often reveal problems. Look for obvious issues like loose connections, damaged wires, or leaks. Inspecting your engine is a basic, yet essential step in the diagnostic process. Visual inspections can help you identify common issues. Inspect the engine for leaks, broken or disconnected wires, and other visible issues.

When the check engine light is on, the computer stores a trouble code. This code can point to the problem’s source, saving time and effort during diagnosis. If the light is on, the first step is to get the codes scanned. Auto parts stores often provide this service for free. Knowing the code lets you understand the nature of the problem, allowing you to focus your attention on the relevant components.

The ability to see live data is a helpful asset when looking at what causes F150 hesitation at low RPM. You can monitor the sensors and see if they’re providing the correct readings. This allows you to track specific engine parameters, such as fuel trims, oxygen sensor readings, and MAF sensor output. The live data feature is like having an X-ray vision for your engine. The information helps you narrow down potential problems. This means you can focus on components that are not working properly.

Many problems can be spotted just by looking. Check for oil or fuel leaks around the injectors, fuel lines, or the fuel pump. Look for damage, such as cracks, corrosion, or wear. Checking the basics can often prevent major issues down the road. This helps you catch potential issues before they cause significant problems. Also, a visual inspection can identify simple fixes. These simple solutions can be implemented quickly.

Case Study 1: Clogged Fuel Filter

One common scenario involves a driver experiencing hesitation in their F150, especially when accelerating from a stop. After a routine tune-up, the owner noticed their truck felt sluggish. Further investigation revealed a clogged fuel filter, restricting fuel flow. This is a real-world example of how a seemingly minor component failure can lead to noticeable performance issues. The driver noticed a lag in power delivery when accelerating from a standstill. This problem worsened as the engine load increased, causing the truck to feel underpowered. Diagnosing the issue involved checking the fuel filter and finding it clogged with debris. This restriction made it difficult for the fuel pump to provide the engine with adequate fuel. Here’s a look at what the diagnostic process can look like.

- Initial Symptoms: The driver noticed a noticeable hesitation and a feeling of being underpowered, especially when accelerating from a stop or at low speeds.

- Diagnostic Steps: The mechanic began by checking the fuel pressure and flow. The fuel filter was then removed and inspected.

- Findings: The fuel filter was found to be severely clogged with dirt and debris, significantly reducing the fuel flow to the engine.

- Solution: The fuel filter was replaced. After replacement, the engine’s performance was restored, eliminating the hesitation, and improving the engine’s power output.

Case Study 2: Faulty Ignition Coil

Another common example is a driver whose F150 suddenly starts misfiring at low RPM. A check engine light is illuminated, and the engine feels rough and hesitant, particularly when starting up. The issue was traced to a single faulty ignition coil. This is a direct example of how a failing ignition component can lead to misfires and noticeable performance issues. The driver noticed the engine sputtering and losing power. They took the vehicle in for a check-up. The mechanic used a diagnostic tool to read the trouble codes, which showed a misfire in cylinder 3. Inspection revealed that the ignition coil for cylinder 3 was defective. Here’s the steps that led to a solution.

- Initial Symptoms: The driver reported that the engine felt rough and hesitant, especially when starting up or accelerating from low speeds. A check engine light was on.

- Diagnostic Steps: A mechanic used a scan tool to read the trouble codes. The mechanic performed a visual inspection.

- Findings: The scan tool showed a misfire on cylinder 3. The mechanic swapped the ignition coil from cylinder 3 to another cylinder to test.

- Solution: When the misfire followed the coil, the mechanic knew the coil was defective. After the mechanic replaced the faulty ignition coil, the engine ran smoothly.

Frequently Asked Questions

Question: What’s the first step when my F150 hesitates at low RPM?

Answer: The first step is to check for any warning lights, especially the check engine light. Then, get the vehicle scanned for trouble codes to see what the computer is telling you.

Question: Can a bad MAF sensor cause hesitation at low RPM?

Answer: Yes, a faulty MAF sensor can definitely cause hesitation. The MAF sensor measures the amount of air entering the engine, and if it’s not working correctly, the engine may not receive the right amount of fuel.

Question: How often should I replace my fuel filter to prevent hesitation?

Answer: It’s often recommended to replace your fuel filter every 15,000 to 30,000 miles, but check your owner’s manual for the specific recommendations for your F150 model.

Question: How can I tell if my spark plugs are bad?

Answer: Signs of bad spark plugs include difficulty starting, rough idling, misfires, reduced fuel economy, and hesitation, especially at low RPM.

Question: Is it safe to drive my F150 if it’s hesitating at low RPM?

Answer: While you can drive it, it’s best to address the issue promptly. The hesitation could worsen or lead to other problems, such as damage to your catalytic converter, if left unchecked.

Final Thoughts

Finding out what causes F150 hesitation at low rpm can be done by a careful approach. As you’ve seen, it could be anything from a clogged fuel filter to a faulty sensor. By understanding the common causes like fuel system problems, ignition issues, and sensor malfunctions, you’re well on your way to diagnosing the issue. Remember to start with the basics: check for trouble codes, inspect components visually, and use a diagnostic tool to gather more data. Don’t be afraid to perform basic maintenance like replacing spark plugs and filters. With a bit of patience and a systematic approach, you can often identify and fix the issue yourself, keeping your F150 running smoothly. If you’re not comfortable working on your truck, always consult a trusted mechanic. Good luck, and keep those engines humming!